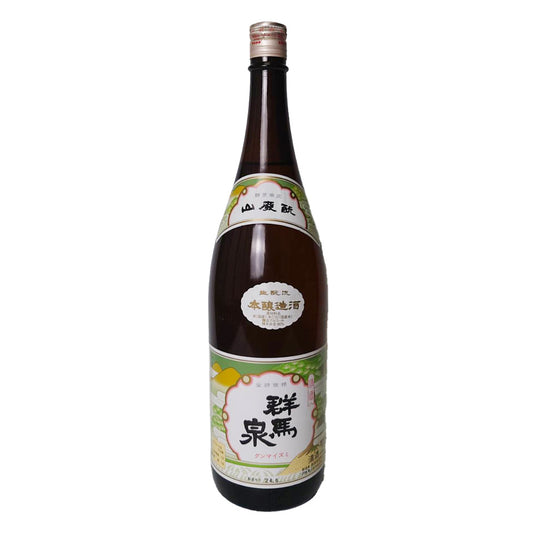

"Even if we evolve, we won't change." Brewing everyday sake (Shimaoka Sake Brewery, Ota City, Gunma Prefecture)

Share

In connection with our new launch of Gunma Izumi in July 2024, we visited Shimaoka Sake Brewery, the brewery, and would like to introduce their sake brewing policy and philosophy, as well as the brewery environment that supports it.

First of all , Gunma Izumi is a sake brewery located in Yura-cho, Ota City, Gunma Prefecture, and is one of the sakes that is extremely popular among experienced sake lovers and food and beverage professionals.

The brewery, Shimaoka Sake Brewery, has been producing just under 500 koku of sake since its founding in 1863 in this area rich in spring water from Mount Akagi (there used to be a Sapporo Beer factory nearby). The brewery uses local sake rice and a "kimoto-style Yamahai brewing" method, carefully crafting sake.

Sake brewing policy

Shimaoka, the current brewer and master brewer, has long been making "everyday sake that you won't get tired of even if you drink it every day," and says, "We don't change the basic flavor," and "We think flashy sake is delicious, but it's different from our own taste."

For this reason, the brewing methods, such as using local Gunma sake-brewing rice (such as "Wakamizuru") and No. 7 yeast, and the ratio of koji and rice used, have remained almost unchanged.In addition, they are extremely committed to brewing sake using the "Yamahaimoto" method and its preservation.

Yamahaimoto is a method of cultivating the yeast starter using natural lactic acid from the brewery rather than using artificial lactic acid in the process of making the starter, and it is a very difficult and time-consuming method that requires delicate techniques to prevent the growth of bacteria. It is extremely difficult to consistently maintain the desired quality of sake using this method.

While the basic structure of sake brewing remains unchanged, every step of the process is constantly being reviewed and "evolved," from washing the rice, the cooling time for the steamed rice, blending methods, and cleaning.

Mechanization would increase efficiency and stabilize sake production, but they do not have the latest equipment and rely on careful, basic work.

The situation inside the storehouse

A Japanese rice cooker for steaming rice (very rare)

Inside the kiln for Japanese pots

The koji room is clean and well-organized, with 5S (the basics of production) thoroughly implemented.

Tanks where sake is prepared and fermented (brewery)

Yamahai yeast starter preparation tank (sake starter room)

This is how Gunma Izumi is brewed and born. It is not flashy, but rather robust and quiet, yet it is a very appealing, high-quality sake that returns to the origins and basics of sake, and we hope you will give it a try.